Multislide

As a specialist for the correct placement and production of pressed and press-bent parts in the manufacturing process, we can look back over several decades of experience in this industry. We are able to use this experience to support you with your order in all areas of production.

Our expertise includes:

-

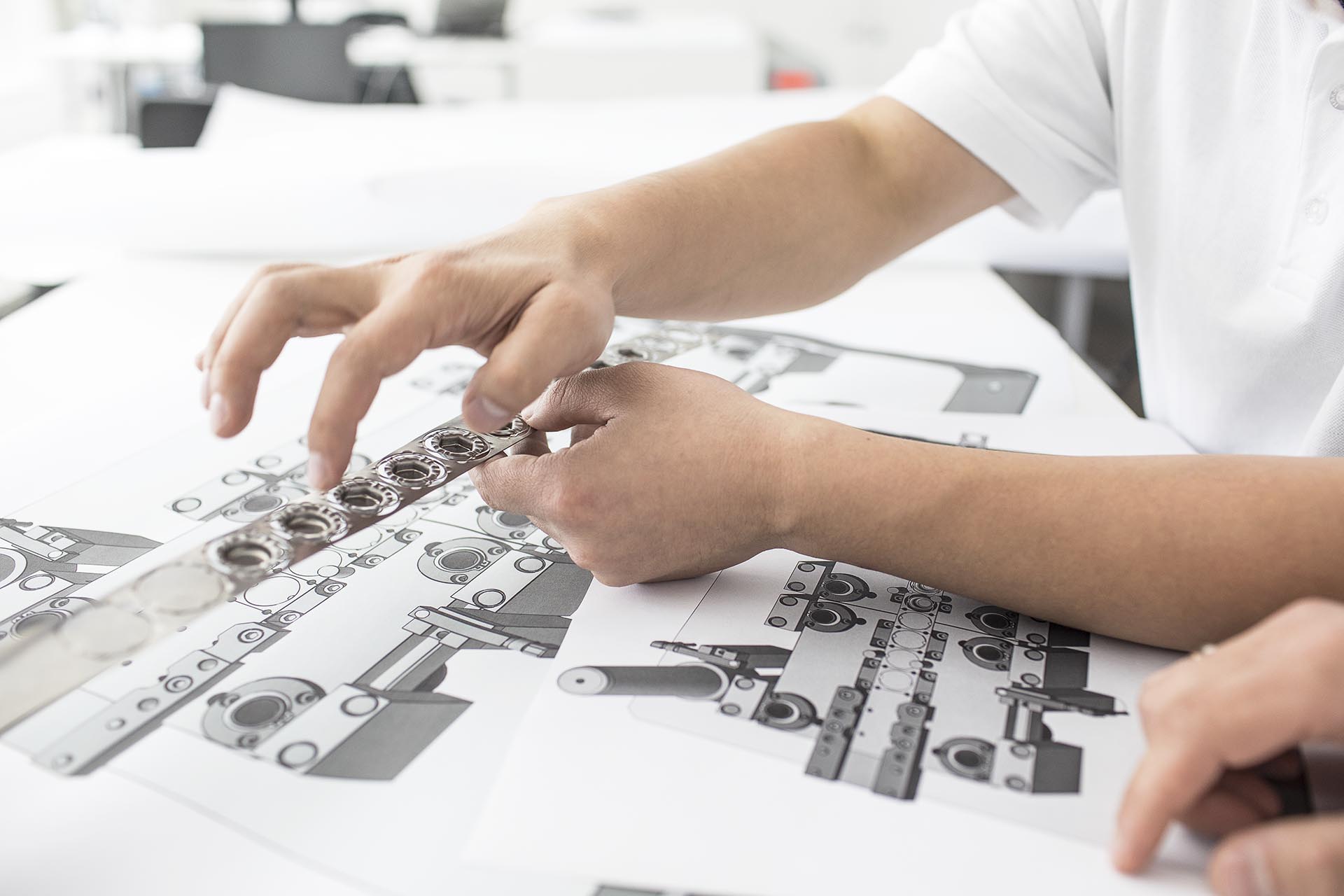

Design and advisory skills for the highest requirements

-

Know-how for structuring outer surfaces

-

Experience in the process of creasing and bevelling

-

Specialist knowledge regarding bending with tight tolerances taking the diameter and seam into account

With our extensive range of machinery, including several multislide machines such as Bihler, we are equipped to deal with the diverse quantity requirements of our customers. We develop, design and manufacture small to large series according to individual customer requirements. Our manufacturing facility is in a position to produce large-scale precision round components quickly and cost-effectively.

Several multislide machines ensure continuous production. After production and calibration in the roll process, additional work stages – from the machine to complete installation – are carried out automatically or semi-automatically after cost-effective optimisation.

Production of sheaths and housing – figures and areas of use

In our multislide department we have specialised in production & manufacture of rolled bearing bushes. We place great emphasis in particular on an overall approach to solutions – The round components are manufactured and calibrated in a rolling process and packaged automatically, if desired. In order to adjust our production optimally to your requirements, partial processes such as individual packaging directly by the machine can be geared to individual needs to facilitate your further processing of the products.

With our efficient production facilities, it’s possible for us to offer a broad spectrum of options to process your product using our pressing and conversion technology.

The most important figures for our technical options during production:

-

Diameter of up to 86mm

-

Lengths from 30 to 120mm

-

Material thickness from 0.8 to 3.5mm

-

Barrelled or rounded edges or shaped installation work-up phase possible

Supported with measurements accompanying the process of multislide together with visual inspections (AOI) of our pressing and conversion techniques, we guarantee correct finishing and compliance with customer requirements in a premium quality.

Our products are used in a very wide range of industries:

-

Vehicle construction (e-motor housing, yoke housing)

-

Plain bearing bushes

-

Sound absorber pipes

-

Shock absorbers for vibration systems

-

Rolled stator package housing

Cost-effectiveness – Calculate and overcome cost factors

One of the most important points in the production of assemblies and multislide parts is cost-effectiveness. Through our experience, we can use an optimal combination of part geometry and materials selection to generate the most cost-effective solution for your requirements.

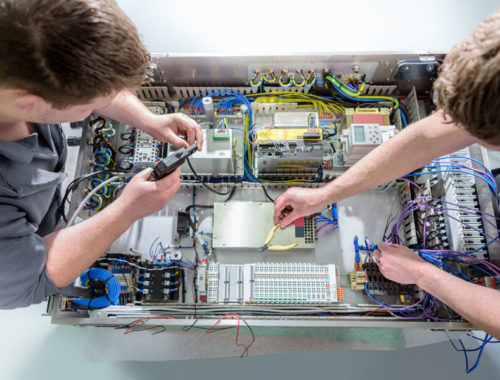

Continuous digitalisation is becoming increasingly important for this. In order to remain competitive, at Kaizhong Vogt we try to use the opportunities of digitalisation and incorporate this into existing company procedures.

As a component of Industry 4.0, we are continually trying to improve the processing of resources by using new technologies. For example, we therefore hope to reduce the multislide reject and error rates even further in conversion processes to supply optimal manufacturing processes for you as our customer.

Premium quality level of our multislide processes

multislide technology to manufacture various components out of steel, copper or aluminium alloys is a combination of many individual processes. Our scope of work includes all areas of pressing techniques.

Starting with pressing the interior and exterior contours, to bending the desired end-contour, we combine various individual processes into one cost-effective, optimised manufacturing process.

If you are interested in collaboration, please contact us so that we can stand at your side during the next stages from advice to the end-production of the finished product.